“Sublimation printing” – If you have ever come across this word, you might be wondering what this can be. Millions of people around the world wear custom printed shirts. But little do they know is the way these garments are made. Sublimation T shirt printing is one such procedure to create custom or personalized products.

It aims at transferring designs from a sublimation paper onto a piece of material/fabric. The shift happens under recommended heat and pressure conditions. The quality of sublimation printing is so high that its popularity has risen exponentially.

How sublimation printing works is a mystery to many; but now that you have arrived at our blog, it’s not a wonder anymore. In this blog, we will be covering what it is, how to do it, how it works, and how long it lasts. Besides, we will be reflecting on the pros/cons, and designs that work well and designs that do not. Stay tuned and read this guide till the end.

What Is Sublimation Printing?

Let’s get started with the broader strokes, shall we?

Simply, sublimation is a particular printing method that transfers a specific design into a fabric or material with heat and ink. To be specific, this procedure involves printing onto a particular sheet of paper. Then the image is transferred onto another material using polyester or a polyester mix. The ink is then heated until it breaks up into the fabric.

Custom apparel manufacturers often use sublimation printing as It’s a game changer in the world of apparel that allows printing of the whole garment with designs that go seam-to-seam. The magic of this process lies in the printing technology. When the designs infuse into the fabric, the design elements become a part of the fabric. Hence, there is no scope for the logos or the colors to fade or peel off in the sublimated garments.

Changing the solid sublimation ink for T shirt printing into a gaseous form is a workable method of customizing products. The high-quality results of sublimation printing have in its worldwide popularity over the last few years.

Nevertheless, this process involves utmost care and perfection.

Otherwise, it may create designs with white creases or ghosting patterns. This in turn can cause you to lose both money and time. Before putting it in bulk, the designers need to get familiar with the process by testing out a few designs on fabrics.

The Process Of Sublimation Printing

Sublimation printing is an eco-friendly technique that is simple and efficient. It gives you an interesting and bright print on the fabric. Some of the top visual artists and designers use this method.

How Does Sublimation Printing Work?

Sublimation printing uses heat to fetch the fabric and ink together as one. You know that when solid material is at a high temperature, it goes into a gaseous phase. At first, this may seem confusing. But the result will woo you.

Wondering how this wonderful process works? Let us help you learn the details.

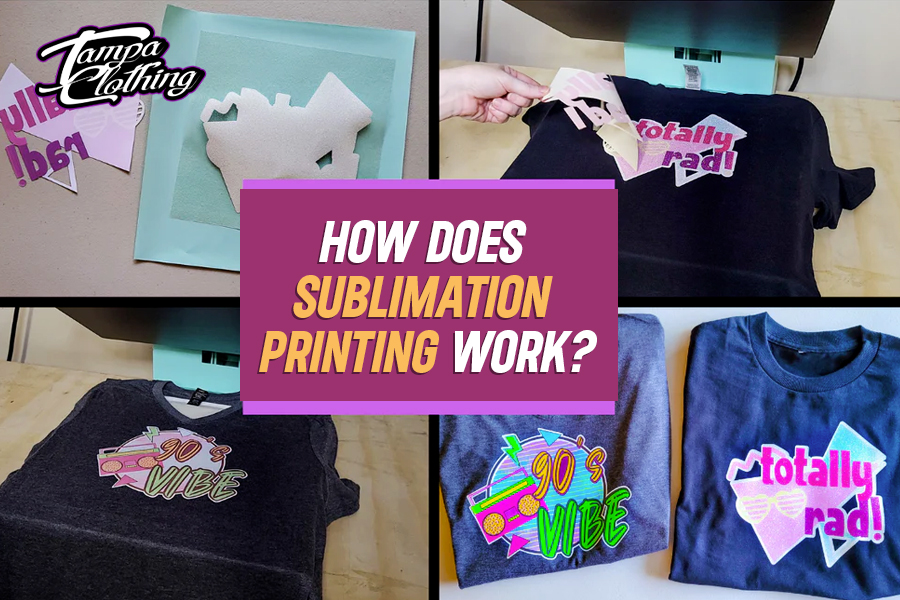

In broad, it is easy to say that the sublimation process involves three major steps:

- Create a design/artwork on a product/apparel.

- Refer the design to the sublimation printer and replicate it onto a transfer paper.

- The use of a heat press is essential for printing the graphic on the product/apparel.

However, the above-mentioned process is just an overview of the detailed ones, which we have discussed ahead. Before that let us give you an understanding of the substances you need for the sublimation printing. They are:

- Sublimation ink

- Sublimation printer

- Transfer paper

- Heat press machine

Now, let us get into the details of the process through which one can perform sublimation printing on any product/apparel:

1. Create a design

The first step for sublimation printing is to create a design. It would be preferable if you customize the design according to your customer’s preference. You must aim to create the highest quality image/design. The better the clarity of your image, the more chances for you to get a high-definition print on your product/apparel through this printing process.

If the image quality is low on the print file, the result of sublimation printing will be dull and blurred.

2. Print design on product/apparel

Before sublimation printing, you must know which product/apparel is it suitable for.

This kind of printing uses ink that comprises dye particles, hence, it is also known as dye-sublimation printing. These dye particles work great with polymers, and polyester-type clothing. The more dye will bond, the sharper, clearer, and more vibrant print you get.

The sublimation printing process is not suitable for 100% cotton items. However, you will be surprised to know that this printing method is also ideal for glass, ceramic, and metals.

3. Using the heat press

The heat press/ transfer depends on the printing machine we use. Different printing machine gives different print quality. It is even seen that the models from the same manufacturers also result in different print quality.

Apart from the above factors, the three most important factors that affect the image in the heating process are:

- Temperature

- Time

- Pressure

What happens during the sublimation printing process?

When kept in a sublimation printer, ink is in liquid form that solidifies after being printed on transfer paper and allowed to dry. When you heat the paper between 350°F and 450°F, the ink becomes gaseous and may transfer to the paper. During the transfer process, a particular transfer paper to the medium with solid ink.

The intense heat and force scatter the ink into the permeable material. You should know that this is different from the inkjet printer where the liquid turns into a solid over the printed media.

An Effective Digital Printing Method

Sublimation shirt printing is an effective digital printing method. It’s rising in popularity for smaller batch orders.

This printing technique is more supportive for miniscule designs than other printing techniques. Sublimation T-shirt printing is also known as ‘all over printing’ as it enables you to choose a design that goes from seam to seam.

Dye Sublimation Supplies

Not every merchandise printing supply is flexible. So, it’s important to think about the materials you would want to use to create custom sublimated shirts.

There are several things to do before printing designs onto your merchandise using sublimation printing. The first thing you need is a special printer that accepts sublimation ink in its cartridges. These printers are designed for both factory and home use.

The second supply required is a heat press that will help in printing the unique designs on the fabric. Just like the printer, sublimation transfers come in a range of models, prices, and sizes to suit different needs. The key function of this heat press is to transfer the design from the sublimation paper onto the requested printing material.

Also read: heat press vs screen printing.

Additionally, you also need transfer paper to create beautiful, long-lasting designs. One can print a customized logo, personal art, any family picture, or any other design onto the paper to print them on the merchandise.

Furthermore investing in a Raster Image Processor (RIP) and a computer is also a MUST for a sublimation printing business. Both these ease color correction. Some sublimation printers come with built-in RIP, but not all of them. Hence, RIP is to be purchased separately. Ensure that the software is compatible with the printer being used.

What Can You Sublimate On?

Sublimation heat transfer printing is the procedure of creating a printed design using sublimation ink with the help of an inkjet printer. The design is then printed onto the sublimation paper or any other acceptable transfer paper. After this, the heat is transferred onto a blank, light-colored sublimation product to do the customization.

To transfer the sublimation ink and make it create a bond with the blank item, the product needs to be “sublimation ready” or “sublimation coated.” This means that the product has a special polymer coating or the material has polyester. There are a large number of products found on the market sold as “sublimation ready” or “sublimation coated.”

This includes, Shirts/T-shirts having 100% or 50% polyester (best shirts for sublimation), ceramic tiles, ceramic mugs, Glass sheets, MDF coasters, polyester bags, aluminum sheets, polyester mouse mats, polyester cushion covers, etc. As long as the substrate includes a polymer coat or polyester, anything can be transferred onto it virtually with sublimation.

The Best Materials To Use For Sublimation Printing

Pure cotton does not work with Sublimation Printing. As full-on cotton shirts are made from natural fibers, they won’t be able to bond permanently with the sublimation ink dyes. Using cotton fabric will transfer the ink temporarily which will later wash out due to an improper bonding between ink dyes and the cotton fibers.

Polyester shirts for sublimation are the best materials to use as the polymers of fabrics like this open up when exposed to heat. As the ink dye is heated, it transforms into a gaseous form and enters easily into the fabric through the pores. As a result, after the fabric cools down, the ink bonds easily.

Polyester also does not form wrinkles easily, so which shirts like these, the chances of white creases or ghosting are also lower.

At times, specialized coatings are used to make the cotton fabric bond with the ink dye. When the polymer is introduced into the cotton fabric, it permanently binds the ink dyes with the fabric. This is how specialized coatings work.

How To Sublimate On Shirts?

The procedure of sublimation may seem a bit complicated but it isn’t if you follow the steps correctly. It’s a process where pressure and heat are simultaneously used to transfer the ink on an item going at a molecular level. This results in a permanent transfer that will remain intact for a long. Many trending shirt designs are printed using sublimation process.

Want to know how to sublimate on shirts? There you go:

First, create a design or download a design in software such as Photoshop, or Silhouette Studio and mirror it. Print the design onto the specialized transfer paper using dye sublimation inks in the sublimation printer. Then preheat the heat press as per the directions mentioned on the heat press. It’s essential to read every instruction carefully to get the best result.

It’s time to cut the butcher paper pieces. You need one at the bottom of the heat press and one between the heat plate and the item (a shirt). Moreover, place another between the shirt to prevent ink from getting onto its back. Place the T-shirt carefully on the heat press and apply the printed design on the shirt. Then press under medium pressure for approximately 45-55 seconds.

Carefully lift the press and remove the butcher paper as well as the sublimation design. Let the shirt cool for a little time and you can remove it from the heat press. That’s it! That is all it takes for sublimation jersey printing or T-shirt sublimation.

How Long Do Sublimation Shirts Last?

Sublimation helps the colors last longer on T-shirts than any other garment printing method. Indeed this is good news! Upon using the best shirts for sublimation printing, you will be able to produce amazing prints that will attract people’s attention. However, certain factors that govern the longevity of sublimation shirts.

These factors include the type of printer, the quality of ink, the type of transfer paper, and the composition of the shirt. The way ink penetrates the polyester fiber, the period of color retention can last up to 10 years easily. Also, due to the fact, the dye sublimation ink is transferred into the fabric instead of on it, there will be no cracks as well on the print.

If any of the above-mentioned factors are not taken into consideration, for instance, if 100% cotton fabric is used, the print will fade after a few washes. It’s therefore essential to make sure the fabric consists of 100% polyester or a minimum of 50% to make the print permanent and non-removable.

What Is the Best Shirt for Sublimation?

Are you about to print Tshirts using dye sublimation or thinking to get one of your shirts customized with Sublimation printing? Then, finding the best shirts to sublimate on is a headache. If you don’t use suitable shirts, the design will fail to transfer and you will end up with a non-sellable Tshirt. In addition, the print will fade and crack in the first wash.

The best shirts for sublimation printing or transfers are polyester blend T-shirts, or polyester shirts. These take the transfer well and make any blank shirt look startling after using sublimation designs. If the shirt consists of 100% polyester, you will get the results exactly the way you want.

It’s true that when polyester garments invariably give the best sublimation printing results. Printing on a white shirt gives the best colors and high-spirited hues. Even if you print on darker shirts the colors will show up still as long as they are polyester. In case you use any other type of fabric such as rayon, silk, cotton, etc., the sublimation ink won’t look vibrant. Furthermore, there is a high risk of fading or transfer failure.

What Materials Can Be Sublimated?

If you are new to sublimation, you will probably be asking yourself, “what materials can be sublimated on?” or “what are perfect materials for sublimation?” Unlike various other printing technologies, dye sublimation embeds the color into the material or the fabric surface easily. This produces high-quality, authentic photographic results thereby making it a great choice for detailed designs.

Needless to mention that sublimation ink stick to only sublimation-ready or sublimation-coated surfaces. This includes Polyester, Blended Man-Made fabrics, sheet materials, fiberglass, polymer-coated items, Wood, ceramics, and vinyl. While polyester is the go-to material for sublimation, it works nicely with blended polyester materials having spandex, lycra, nylon, etc.

There is a range of sheet materials that work perfectly with dye sublimation. PVC sheets, high-temperature plastic sheets, and polymer-coated aluminum are such materials. Too, reinforced plastic material made of glass fibers or a textile fabric composed of woven glass filaments works fine.

Talking about polymer-coated plastic materials, plates, bottles, notebooks, cups, Tupperware, and business cards are acceptable materials. Surprisingly sublimation works on wood if protected with polymer coating, otherwise, it will burn.

How To Sublimate On Dark Colors

The best full sublimation shirt design on a black or dark-colored fabric can be achieved successfully using specialized products. The ink you will be using for this type of full dye-sublimation Tshirt printing is white.

Also, the garment should be fully polyester or 50% polyester without any dyes so that it absorbs the lights and doesn’t bounce any colors back. Below are the steps you need to follow:

First, load an inkjet printer with dye sublimation ink. Now to create a print, prepare the design according to your choice. The cloth should be polymer-coated or at least 50% polyester-containing garment. You should go for a programmable shirt printer machine or a Silhouette Cameo.

As the second step, put a piece of white paper under the transfer paper of black dye sub polyurethane to get the dark ink printed onto the light shirt. This will look like you are doing prints on the color shirt.

There are many transfer papers available in the market that work with dark shirts. Now, lay the transfer paper, dye-sub polyurethane, onto the Tshirt in a face-down way.

The temperature you need to adhere to for the transfer paper is 392 degrees Fahrenheit. Press the iron/heat press close with medium to heavy pressure for 10 seconds to 4 minutes.

Essentially, the heat press time depends on the material you are using to which the design is transferred. After pressing, examine the shirt for color transfer and let it cool and you will get your customized black sublimated shirt.

Sublimation Printing Fabric

The fabric you are using matters a lot when it comes to Sublimation Tshirt printing. Sublimation is one of the most proven methods of printing on synthetic fabrics, giving a fully permanent print every single time.

It’s suitable for garments having 100% polyester or polyester blend. Although it’s not impossible to do on other fabrics such as cotton, the image won’t be permanent like ‘man-made’ fabric.

As a result, only polyester-based garments are recommended if you want to get the best and the most durable results. Natural fibers like silk, cotton, or wool can’t create a bond with the sublimation ink as they don’t absorb the dye adequately.

As long as the fabric of the material contains at least 50% polyester, it’s possible to be printed using sublimation. The higher the synthetic content, the better the image vibrancy, quality, and longevity. Other than this, blended polyester fabrics spandex, lycra, and nylon also work.

Sublimation Heat Presses

The heat press is a necessary sublimation printing supply. It’s required to press and heat the designs for enabling the transfer. No wonder heat presses come in different sizes. Therefore, ensure the one you are getting has a large heat plate to handle all the designs you want. Please note, that iron is not an alternative to a heat press. Therefore, it won’t get the job done.

The market is flooded with a myriad of heat presses – from budget-friendly to those that are more applicable for commercial purposes. What size of heat presses you will be looking for largely depends on the reason you are using them for.

There are different models in the market specifically for those who want simple Tshirt designs and also those who want a range of functions.

Make sure to read the reviews and instructions before you purchase a heat press online. Investing in one machine offering multifunctioning and is also lightweight is the best option. It’s true that among all the other supplies, the heat press is the most expensive equipment but without it’s not possible to design the prints correctly.

Designs That Work Well With Sublimation Printing

The majority of screen printing’s shortcomings are eliminated through sublimation. People love sublimation cloth printing so much because of the amazing advantages it provides. One of them is its flexibility with many startling designs. Let’s check them out one by one below:

Sublimation printing works well on dramatic, quirky, and aesthetic designs which are massively on trend over the last few years. These days, you will find many high and low-end stores that have adopted the sublimation printing process.

A sublimated Tshirt falls under the categories of quirky, aesthetic, and meaningful garments. Additionally, sublimation printing makes it possible to get the entire impact.

Photography prints are another design style that complements sublimation printing pretty well. The technique enables you to cover the entire surface with the image rather than just arranging it in a rectangle pattern on the front of the garment. However, in this case, the angle of the photo needs to be taken into account.

When your clothing needs a variety of distinct logos or designs, sublimation also works nicely. With standard printing, you could have to pay for each logo application. But, with sublimation, several can be combined and printed at once.

It’s advised to find a clothing manufacturer who has true expertise in dye sublimation printing & other shirt printing methods.

Your design will stay as long as the outfit does because the ink is virtually integrated into the fabric. The flexibility offered by dye-sublimation printing is an additional key benefit. The pattern is frequently stretched and distorted when printed on traditional clothing.

Designs That Don’t Work With Sublimation Printing

Sublimation can be conducted with almost any kind of material; however, not every form of sublimation Tshirt design goes well with this procedure.

For instance, designs requiring exact placement or designs with block colors may not work well with this process rather to designs involving direct-to-garment (DTG) printing or slogan printing. While DTG printing is almost like using a typical printer, it’s just meant for T-shirts. The garment is, therefore, run through a flatbed printer using, which the designs are applied.

Related: Explore the difference between DTF and DTG.

In addition, if you need just one logo at the center of your shirt, sublimation steps are not ideal for you. This is because sublimation is generally expensive as it requires printing all over than applying one logo or at the center of your shirt.

Moreover, this printing technique uses special inks and printers which increase its cost more than that of other techniques. One of the tips to use sublimation printing efficiently is knowing all the limitations beforehand and choosing a design wisely.

Also, it’s advisable to do sublimation on a light-colored garment, preferably white. Dark-colored surfaces, especially black aren’t possible to be sublimated. The item may lose color over time when it comes in contact with UV rays if it’s exposed to direct sun rays. Keeping these disadvantages in mind, you must go for sublimation printing.

What Hacks Can Be Used To Create Clothing Through Sublimation?

Not every attempt at sublimation is successful. Sometimes even trained and experienced designers fail to bring out the perfect result. Do you want to get the most out of sublimation Tshirt printing? Here are some tips that will surely make the sublimation process successful. Check these out:

1. Take The Measurements Accurately

To sublimate an image perfectly on your items, take the necessary measurements accurately. Getting the right dimensions is crucial; so it’s better to take the help of the templates that will ensure a flawless fit.

2. You Can Use Matte Paper Or Copy Paper Instead Of Sublimation Paper

Using copy paper, matte paper, and sublimation paper and following the right procedure will give desired results. Also, it will reduce the expense to a considerable extent. However, we would still recommend using a sublimation paper for the best results.

3. Remove Protective Covering and Use Polyester Coating

Some sublimation blanks come with a protective covering. So make sure to check the blank to remove the covering before printing. Either a synthetic material blend or polyester is required for the ink to be fully absorbed into the material.

During the heating process, this will result in a print that is crisper and more colorful. You may also use a pre-coated sublimation blank.

4. Check The Moisture

If you operate in a wet environment, be wary of humidity. On your design, moisture might lead to flashing, which wipes the ink from the selected area. We advise keeping your paper in a dry environment. It might be kept in a sealed bag or a container.

When dealing with clothing, you may also pre-press the material for 10 seconds wick away moisture, and smooth out creases. A dehumidifier may be installed within your workstation to remove moisture from the air.

5. Be Careful About The Heat Press Temperature

To make sure the design of the sublimation on the shirt is moved onto the garment correctly, it’s important to check whether your heat press temperature is okay.

Take the help of a digital thermometer to ensure the heat press has the recommended temperature. In case, the temperature is too low, the item will be undercooked while if it’s too high the shirt will get scorched.

6. Secure The Sublimation Paper To The Material

The sublimation paper must remain in place securely on the material at the time of the heat-pressing process. Even the slightest movement can lead to ghosting – a shadowy effect that will ruin the design of the shirt. To secure sublimation paper to the blank, use a heat-resistant spray, or an adhesive spray.

7. The Printed Image Should Be Bigger Than The Object

This provides for a margin of error that, if it arises, may be quickly managed. If you print it smaller, there will be a lot of white areas since the design won’t fit properly onto the cloth. Similarly, to this, any mistakes will be more noticeable.

Is There White Ink in Sublimation Printing?

Recently, white toner has attained popularity to customize fabrics according to customer’s choice, and they often ask whether there is white ink in Sublimation Printing.

To answer this, there is nothing known as a white sublimation printer. Printing in white with sublimation on light-colored textiles is outdated now. It’s because the color reproduction is perfect with magenta, black, and yellow sublimation ink.

Since sublimation gives the best results on light grays, whites, and pastel colors, the machine can’t print white color. As the sublimation ink is transparent, the color of the base material will be visible partially. Any white dye in a gaseous state trying to get printed onto a black polyester fiber will be contaminated by the tone of the fiber only.

The industry has identified the need to print white designs on darker polyester over a long time and has also tried to address it. As a solution, often specially coated 1 or 2-step transfer papers are used that enable the designers to use the sublimation printer they already have with dark polyester or other types of textiles.

Can You Sublimate Onto Anything?

As long as the substrate is polyester or polyester coat, anything is possible to be transferred onto it virtually using the sublimation printing technology. For the best results, it’s recommended to use this procedure with polyester materials.

It may also be applied to a variety of surfaces with specialized polymer coatings, including those on mousepads, mugs, coasters, and other items. Glass may also be sublimated in specific circumstances. However, it has to be glass properly cleaned, and prepared with a specialized spray.

Apart from this, other blended materials will also work provided that they contain 50% polyester. Some other great options are lycra, spandex, and nylon. Since these are man-made materials, it becomes easier to absorb the ink and retain it for a longer time.

When it comes to garments composed of 100% cotton, the answer is YES, you can sublimate on them effectively but they won’t last after washing and will fade away. If the cloth is made of 50% polyester and 50% cotton fabric, then only 50% of the sublimation will remain.

Pros And Cons Of Sublimation Printing

Sublimation is a fantastic option for the finest details and lines and is undoubtedly one of the best methods for all-over printing. It’s great for small runs since it has low set-up costs. The printing is also almost permanent and of high quality. There are many more advantages of dye sublimation t shirt printing that captivate customers who love customized garments.

However, there are some disadvantages too, which you should know before going for sublimation on shirts or any other items. Below are the pros and cons of sublimation printing explained in detail. Take a look at them to be aware of both the positive and negative sides.

Pros Of Sublimation Printing:

- It Enables Personalization And Customization: One of the biggest plus points of sublimation printing is that it gives freedom in terms of personalization. You can modify the quality and the size of the image to be printed and address the errors occurring on the printer. In this way, you can become more creative and bring your ideas to life.

- It’s A Quick Process: Sublimation is a faster process. It’s convenient for people who want customized T-shirts with a strict deadline. Since it uses high-level technology, this method works a lot more efficiently in comparison to the other methods requiring human power.

- Creates High-Quality Designs: The quality of the designs created using Sublimation Printing Technology is quite better than any other type of printing. The vibrancy is great as well as the Dots Per Inch (DPI) although it depends on the printer you have purchased.

- Sublimation Creates Long-Lasting Designs: Sublimation printing, especially all-over sublimation t shirt printing gives results that won’t peel, or fade, unlike other designs. It’s due to the absorption of the ink instead of making it just a layer on the fabric. This means you can wash the shirt as many times as you want without worrying about quality degradation.

Cons Of Sublimation Printing:

- Ghosting: One of the major disadvantages of Sublimation printing is that Ghosting occurs when the transfer paper shift at the time of heat pressing. The print will have a light faded spot in it that looks like a ghost. Not only it would take your effort and time, but also the customization will not be up to the mark. If the ink on the transfer paper is not dry enough or excessive pressure is applied, issues like this arise.

- White Creasing: Sublimation often gives rise to another disadvantage called White Creasing. If there are any areas on the requested product that the design didn’t reach, it forms white creases. This happens again if the transfer paper is not dry enough or any area of the shirt is folded. White creases lower the quality, and the Tshirt will become unsellable.

- Restricted To Polyester Materials: Sublimation Printing is not suitable for every type of material. Especially in terms of shirts, or Tshirts, the fabric has to be 100% polyester or at least 2/3 of polyester to get desired results. Otherwise, the design will eventually fade after repeated use and washes.

Is Sublimation Better Than Screen Printing?

If done correctly and if proper technologies are followed both, Sublimation and screen printing can last longer. Each printing technique indeed has advantages of its own. Nonetheless, there are a few important aspects to take into account when selecting whether dye sublimation or screen printing is preferable:

Order Size This is typically the first thing to take into account. The higher the volume of the order, the more time-consuming will it be for sublimation printing. On the other hand, screen printing is the best solution for bulk orders as it is done quickly.

As a result, sublimating a shirt is best for smaller orders. Most sublimation printers have a specific minimum order quantity for their printing services.

1. Job Setup

One of the most prominent limitations of the screen printing technique is that the substrate takes one color only at a time. Plus the alignment of multiple layers of color is also an added concern, and the setup times could be extended when more than one color is involved.

Sublimation, on the contrary, doesn’t create an issue with the alignment of each color as this procedure prints all the colors at once. It becomes easy to customize the designs with this process as you have to only change the design and make another print of the new transfer to execute the changes.

2. Choice Of The Materials

Both, sublimation printing, and screen printing are two recent gimmicks in the customized products industry. They can rule out or rule in specific printing processes.

Screen printing is highly versatile concerning the materials of what you are printing value. The dye sublimation process is suitable for pure polyester or polyester mixed materials that are either light in color or white.

What’s The Difference Between Sublimation Printing And Digital Printing?

Sublimation printing differs from digital printing in a myriad of aspects. Both, these printing technologies are becoming increasingly popular day by day and have their own advantages and disadvantages. These pros and cons lay out the differences between them.

The key difference between sublimation and digital printing is that digital prints are printed on particular materials’ surfaces. On the other hand, in the dye sublimation process, the prints are infused into the requested material. While the former is susceptible to peel, scratch, or chip, a sublimation print cannot be damaged.

The next difference is related to the printing material. Digital printing helps to print a design onto silk, cotton, and polyester primarily. Oppositely, sublimation is appropriate only for polyester products. If not 100% polyester for the best results, then the material should contain at least 50% polyester. Otherwise, the designs will wear off.

The sublimation procedure requires using high heat but digital printing works without the heat application to print the design onto the material.

The key objective of sublimation printing is to produce high-quality, durable designs. The designs created by digital printing are not fully absorbed by the printing paper. It often leads to cracks in between the color. It’s also costlier than sublimation and gives out a higher amount of liquid waste if the right printer is not used.

The printing format you choose depends on the type of products you want to create. Both, sublimation and digital printing are simply great techniques, and a range of supplies are available in the market.

It’s crucial to measure the pros and cons of each method when thinking and deciding about your goals. Especially in terms of Sublimation, the results are better when all these factors are considered beforehand.

Get Customized Sublimation

When it comes to producing full-color, high-quality images for clothes and other items sublimation printing is a fantastic option. There is rarely any downtime, which makes each production lucrative and enables you to produce as much merchandise as you like. It’s one of the most affordable printing techniques available that produce mind-blowing results if the steps to sublimation printing are followed correctly.

The customization that sublimation printing delivers attracts people who love to wear personalized clothes. As a result, it’s profitable enough.

With this personalization, you may completely satisfy a customer’s expectations and create a range of styles to appeal to various preferences. It enables individuals to turn their work from the computer into reality in a quick and simple procedure.

Tampa clothing creates high-quality, customized sublimation printing apparel the way you like. Being the best custom apparel manufacturer in the USA, we are proud of our work. If you want to get your custom shirts with sublimation prints, get in touch with Tampa Clothing, and we will give you what you want.

From start to finish Bryan is your go-to contact he will guide you through the setup and design process while making sure all your needs are met!